In recent years, with the development of fine pitch LED displays, people have higher requirements for display performance and display effects. In this context, GOB technology has emerged. With high-performance protection technology and exquisite display effects, it has quickly gained recognition in the industry and become a "hot potato" in the LED display screen industry.

What is GOB technology?

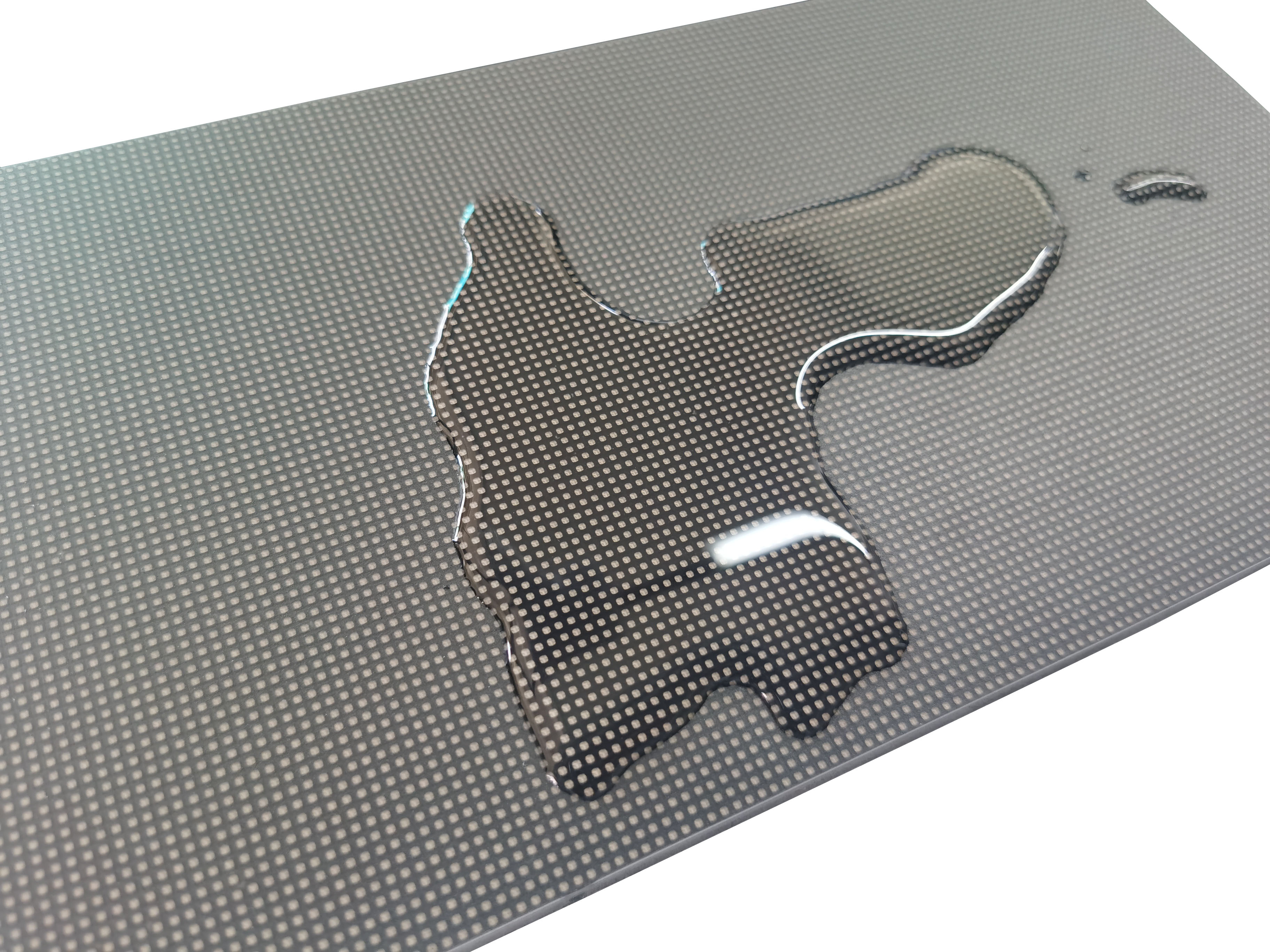

GOB is the abbreviation for GLUE ON THE BOARD board adhesive. GOB technology is a new type of optical thermal conductive nano filling material that uses a special process to achieve a frosting effect on the surface of LED display screens by treating conventional LED display screen PCB boards and their mounting beads with double fog surface optics. It improves the existing protection technology of LED display screens and and innovatively realizes the conversion and display from point light sources to surface light sources.

The high brightness of LED screens is its advantage, but it is also a disadvantage of indoor applications. The high intensity of light, high-frequency refresh, and particles on the surface of the lamp beads make LED indoor displays particularly prone to visual fatigue when faced with "close range, long viewing time" command and dispatch center applications, which is a disadvantage that many customers cannot accept. However, GOB small spacing technology can eliminate the "visual experience disadvantage" of these traditional LED screens.

Now GOB 2.0 is coming

After years of GOB processing being used, some shortages have been found. In recent 2 years, the company has Researched better and more suitable material and developed the processing skill, now the GOB 2.0 is coming and Start Execution.

It works better in heat dissipation. It performs better in uniformity.

Scope of application of GOB technology

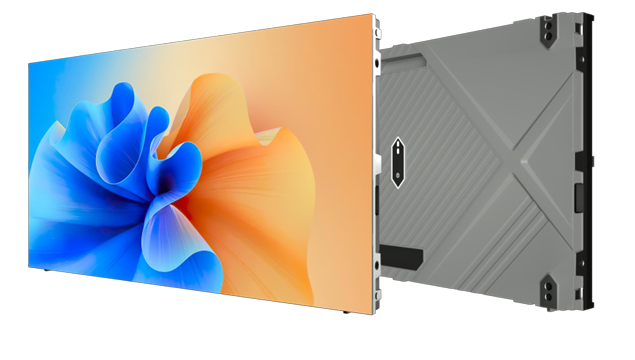

The GOB process supports various LED displays. For example, indoor LED screens, outdoor LED screens, small pitch LED screens, independent chip holographic transparent screens, LED tile screens, LED irregular screens, etc.

The advantages of GOB technology

8 precautions: waterproof, moisture-proof, anti-collision, dustproof, anti-corrosion, blue light proof, salt proof, and anti-static.

Its matte effect significantly improves the color contrast of the product, reduces glare, and reduces visual fatigue.

The transformation from a point light source to a surface light source has been achieved, making the product's luminescence more uniform, greatly improving the product's visual angle, and effectively eliminating the problem of LED display screen spots.

Shielding adhesive helps to dissipate heat, reduces the rate of lamp bead necrosis, makes the screen more stable, and extends its service life.

GOB technology combines midstream packaging and downstream display technologies in the LED industry, saving manufacturing costs and improving production efficiency. And the smaller the spacing, the more obvious the comprehensive cost advantage of GOB products. In addition to technological and cost advantages, GOB products also have better performance. The defect rate in the lifecycle of GOB products is nearly an order of magnitude lower than traditional SMD products, which can better meet the ultra-high definition intelligent display needs of the 5G era and has differentiation advantages in small spacing display.

P0.9 / P1.2 / P 1.5 / P1.8 / P2.5 LED cabinet - Thinnest design is 28mm

Wellvision

Wellvision